How To Cut Deep Slots In Wood

- How To Cut Deep Slots In Wood Floors

- How To Cut Deep Slots In Wood Lathe

- How To Cut Deep Slots In Wood Stoves

I’m working on a new woodworking project that involved cutting through-slots for bolts in a couple of boards. The two boards will act as adjustable arms to hold a dowel handle for a garden cart.

How To Cut Deep Slots In Wood Floors

I have cut shorter and narrower slots using a table-mounted router for a coin bank. These bolt slots were considerably longer and 1/4' wide so I was reluctant to use the same technique. I don’t have a plunge router – which would probably be the fastest and easiest way to do this.

- Slot Cutters Create perfect slots for splines in your glue-ups, or make t-slots for your own slat wall. These router bits by Whiteside are 100% made in the USA, rated #1 by Fine Woodworking magazine, and guaranteed.

- Slot hinges are a great solution for a project with thin walls and help you to avoid splitting the walls. George Vondriska is joined by AJ Moses to discuss how to cut accurate slots for slot hinges. Using a drill press and a simple jig, AJ demonstrates an easy way to cut these slots, similar to using a biscuit joiner.

- Alternatively, cut the slots after assembly with a biscuit joiner set for a #20 biscuit or with a router outfitted with a 3⁄8'-deep slot-cutting bit and bearing (Photo D). When attaching the tabletop, position the clips far enough from the side aprons to allow the appropriate amount of cross-grain wood movement.

Crowd-sourcing ideas

After checking a couple of woodworking forums for ideas – including one where someone trying this on a router table said the board 'shattered' (yikes!) – the general consensus seemed to be todrill out most of the material and clean up the slot later with a coping saw.

For some renovation work, I need to replace a piece of 'filler wood.' It's two inches wide, about 25 inches long, and about 1/4+ inch thick (I cut it out of a piece of wine crate). It fits on one side of the slot it has to slide into, but is about a mm too thick on the other end. If the wood is being fed in the direction shown below it is called climb cutting and can be very dangerous. In a climb cut, the bit is cutting on entry and has the effect of pushing the router away from the workpiece. If not resisted by the operator, the bit can exit fully from the cut and 'climb' its way along the workpiece.

That sounded good (and safe) to me.

How To Cut Deep Slots In Wood Lathe

Since my slot was only 1/4' wide, I decided best approach was to use a 1/4' Forstner bit in a drill press to define the slot and remove most of the material, then clean up the slot with a file and sandpaper.

The shaft on the 1/4' bit was larger than the bit itself so I had to flip the board over to drill all the way through the 3/4' material. It’s probably a good idea to do this anyway to avoid tear-out unless you have a backer board underneath when you’re drilling.

What to do

How To Cut Deep Slots In Wood Stoves

Drilling

- Mark the centre points for each end of the slot in the blank and use a nail or awl to punch a small hole for orienting the bit.

- Set up the drill press with a Forstner bit the same size as the slot you’re cutting. You’ll need to attach a fence to the drill press table to maintain a straight line as you drill along the length.

- Place the blank against the fence and lower the bit. Adjust the fence and blank so the point of the Forstner bit enters the small punched hole. Clamp the fence in place, slide the blank to the mark at the other end of the slot and check that it’s aligned properly.

- Put a mark on the edge of the board that’s against the fence. Keep this edge against the fence when you flip the board over and drill the other side. This ensures the holes are in line even if your a hair off centre of the board.

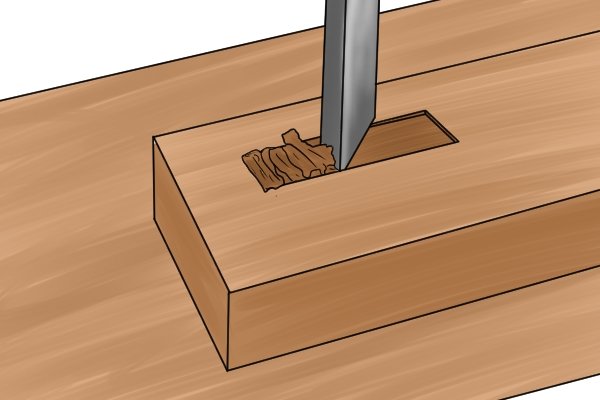

- Turn on the drill press and drill the each end hole to define the slot – drilling about two-thirds to three-quarters of the way through the board. After that, just keep drilling holes and moving the work piece along the fence, overlapping holes just enough to keep point of the bit entering new wood. The slot will fill up with shavings which you should clear out if they get in the way.

- Once you’ve drilled the length of the slot, clean it out with a screw driver or something similar. Flip the board over (keeping the same edge against the fence).

- Repeat the process starting with the end holes. It doesn’t matter which direction you work in.

A COUPLE OF NOTES:

- If you’re making a wider slot, you may want to make an additional pass to remove the 'peaks' between holes.

- If you have a mortising chisel & bit you could swap that in once you’ve drilled the end holes.

Cleaning up the slot

- After the drilling is complete, clean out the shavings with an awl or small screwdriver.

- Clamp the work piece on edge to your bench and use a flat file to remove the high points left between the drilled holes being careful not to hit the rounded ends of the slots.

- Wrap a small piece of sandpaper around a drill bit (smaller than the slot) to sand the ends of the slot.

- After filing off most of the rough surfaces in the slot, wrap some sandpaper around the file and use it to finish cleaning up the slot.

If the slots were 1/2” wide or more, I probably would have used a jigsaw and straightedge to clean up the slots before sanding.

| Simon Reeves | 12/10/2010 18:11:39 |

622 forum posts 227 photos | I've been asked to make a pair of scroll holders for a colleague who is doing a BA in art. These are basically a 250mm plain wooden shaft, 20mm diameter, with slightly larger turned and decorated ends. The problem is, he wants a 1mm slit, 5mm deep along the length of the shafts in order to secure the parchment in and to cover its ends. Anyone have any ideas how to go about this, bearing in mind how fragile a small router cutter (or similar) might be, the depth of the slit, and the need to keep it dead straight? Thanks |

| Doug | 12/10/2010 18:44:40 |

3415 forum posts 35 photos | With such a narrow slit i would probably use a dremel with a round wood cutting blade. I`d make a simple jig to run the body of the dremel against to keep it straight. Baz |

| Big Al | 12/10/2010 18:56:03 |

| 1601 forum posts 73 photos | I have never come across a 1mm diameter, although a quick look on wealden's web site shows that they stock them, but they only have a 3mm cut length so you wouldn't be able to cut to the depth that is required. A small slitting saw blade for a dremel or similar tool should do what you want, failing that some sort of scratch stock with a knife might work. Al |

| Ralph Harvey | 12/10/2010 23:34:42 |

| 3274 forum posts 315 photos 2 articles | Just a thought, cant you cut a wider groove about 6mm and a fill piece 5mm to fix the parchment in place, it will be easier to cut and easier to attatch the parchment, it might be a bit fiddly to get the parchment in a narrow slot.? Ralph |

| Andrew F | 13/10/2010 01:25:48 |

| 3 forum posts 2 photos | How about cutting the slot in a square blank of wood then turning round would be easier to hold and cut. Or Laminate the blank from 2 pieces of wood with a 1 x 5mm rebate cut in one piece. This would ensure that one edge of slot would be in line with centre. Andy |

| Victor Hamshoo | 13/10/2010 18:04:41 |

| 21 forum posts | Why not send a PM to an expert Simon, try these guys I'm sure they'd be more than happy to help http://www.getwoodworking.com/forums/postings.asp?th=39966 |

| Victor Hamshoo | 13/10/2010 18:06:46 |

| 21 forum posts | Whoops that did'nt turn into a 'linky', ????? |

| Simon Reeves | 14/10/2010 13:12:01 |

622 forum posts 227 photos | Thanks guys. All good suggestions - I quite like the idea of a wider slot with a filler from Ralph and the laminated one from Andy. Certainly both would be easier than trying to cut the 1mm slot directly, and could be made using a table saw or router table, . As I've got to make 2 of these, I might give both ideas a try. I'll post the end result (assuming it doesn't all go horribly wrong!). Thanks again. |